About

Rocket Propulsion Group is an Aerospace team focused on the development and research of solid propellant rocket motors. The team's goal is to eventually participate in Spaceport America Cup in New Mexico in the Student Reasearch and Design category. Recently RPG has been focusing on designing and building their first rocket motor using the MIT recipe Cherry Limeade as well as setting up their testing and mixing sites for current and future uses.

Sub-Teams

Propulsion

Responsible for development of hybrid motor

Motor Fabrication

Modeling/Simulation

electrical

Responsible for integration of electrical components into the rocket

Avionics Package

Recovery Electronics

Rocket Payload

Telemetry and Video

Motor Valve System

SIMULATION

Responsible for rocket design and simulation

Flight Modeling/Simulation

Motor Modeling/Simulation

Finite Element Analysis (FEA)

STRUCTURES

Responsible for rocket design and fabrication

Flight Modeling

Recovery System

Rocket Fabrication

EXPERIMENTAL PROGRESS

Below are the 4 main team groups and their descriptions.

ELECTRICAL

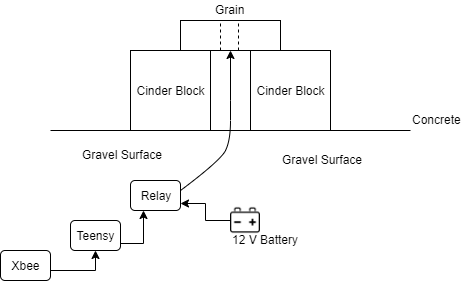

The electrical team has been working on the electrical valving system for the upcoming small-scale static fire test as well as the system for the full-scale system.

Recently, the team coordinated with the propulsion team to make the ignition system for the solid fuel grain “smolder test.”

Now, the electrical team is budgeting for new valves and working on levels of safety in the valving system.

PROPULSION

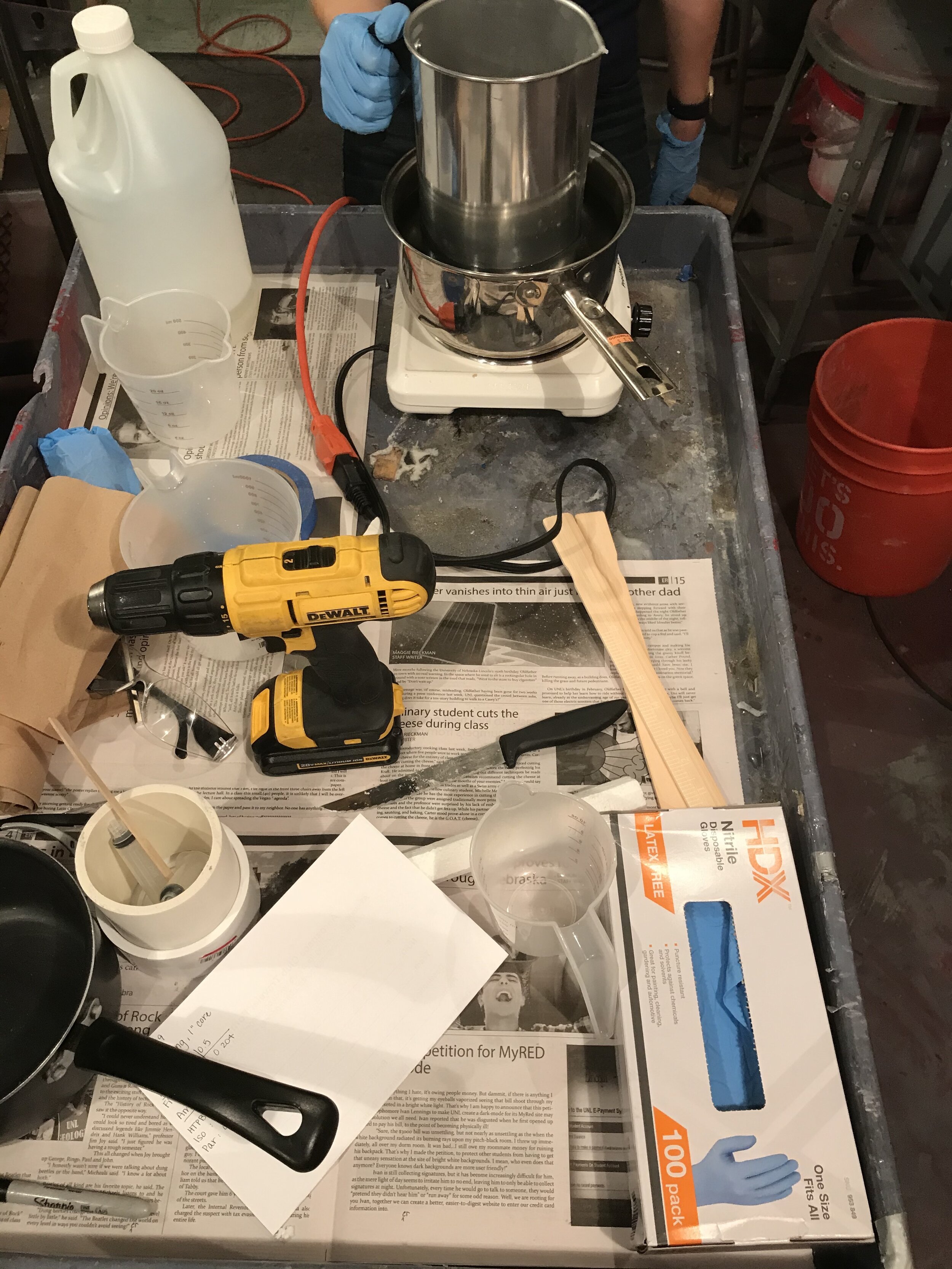

The propulsion team has been fabricating small fuel grains made of a 1:1 ratio of HTPB and Paraffin wax. The team cast the solution in a PVC pipe and used styrofoam cores, which later is removed with acetone, to create a hollow center. The team has just started testing multi-layer fuel grain fabrication in order to prepare for the small-scale static fire test with a larger fuel grain.

After fabricated multiple small grains, the team performed a “smolder” test to test different ignition methods. Now, the team is fabricating their own ignition method and finalizing the fuel grain development process.

simulation

The simulation team has been modeling the experimental rocket in OpenRocket to run simulations required to construct the rocket.

They will also be conducting FEA on the small-scale static fire combustion chamber, valving system, and testing frame.

structures

The structures team previously started designing the entire rocket as well as the payload system. For the small-scale static fire test, they have designed and manufactured a steel frame for which the combustion chamber can be mounted to during testing. They also have been designing and assembling the valving system for the liquid fuel.

TEAM DYNAMIC

The 100K Aerospace Team is a team that is continually advancing and collaborating effectively. Below are images of members writing a professional safety report (left) and socializing during a breakfast event (right).

Sponsorship

Thank you to our sponsors for supporting our project and providing an opportunity for students to gain experience in the aerospace engineering field.

To see a full list check out our sponsors page!

If you are interested in funding our team or have any questions, please contact us using the form below.